Structures similar to that of Graphene have been known since the 1960s, but at that time it was difficult to isolate the individual floors in them. This wonderful material was first isolated in 2004, thanks to Andre Geim and Konstantin Novoselov of the University of Manchester, using the method known as: the “scotch-tape” method. The isolation of Graphene, to the two Professors, earned him the Nobel Prize in Physics in 2010.

Graphene (Gr) is a single monatomic layer of sp2 hybridized carbon atoms arranged in a hexagon with a C-C distance of 0.142 nm.

It represents the first true two-dimensional crystalline (2D) material. It has exceptional chemical-physical properties, which make it interesting in a large number of potential applications. Thanks to the presence of double covalent bonds between the carbon atoms it is very physically stable. It is extremely resistant and rigid (100 times more than steel, Young’s modulus 1.0TPa), transparent, flexible, very light. It has a surface / mass ratio of 2600 m2 / g. Furthermore, it has an electrical conductivity higher than any other substance at room temperature. The thermal conductivity is also high, 5.3×103 Wm / K and the optical transmittance 97%.

An interesting application property is its ability to act as a capacitor to accumulate electrical energy. But the list of possible applications is endless: conductive materials for touch, displays, sensors, membranes, electrodes for batteries, integrated circuits, photodetectors, photovoltaic cells, transistors, quantum dots, spintronic devices, DNA sequencers, fuel cells, desalination devices. water, thermal coatings, shield coatings, functional fluids, waterproof films, barriers, conductive inks, antennas, biosensors, optical devices, lubricants, biomedical devices, 3D printing materials, paints, composite materials and more.

Due to its structure, Graphene allows infinite modifications.

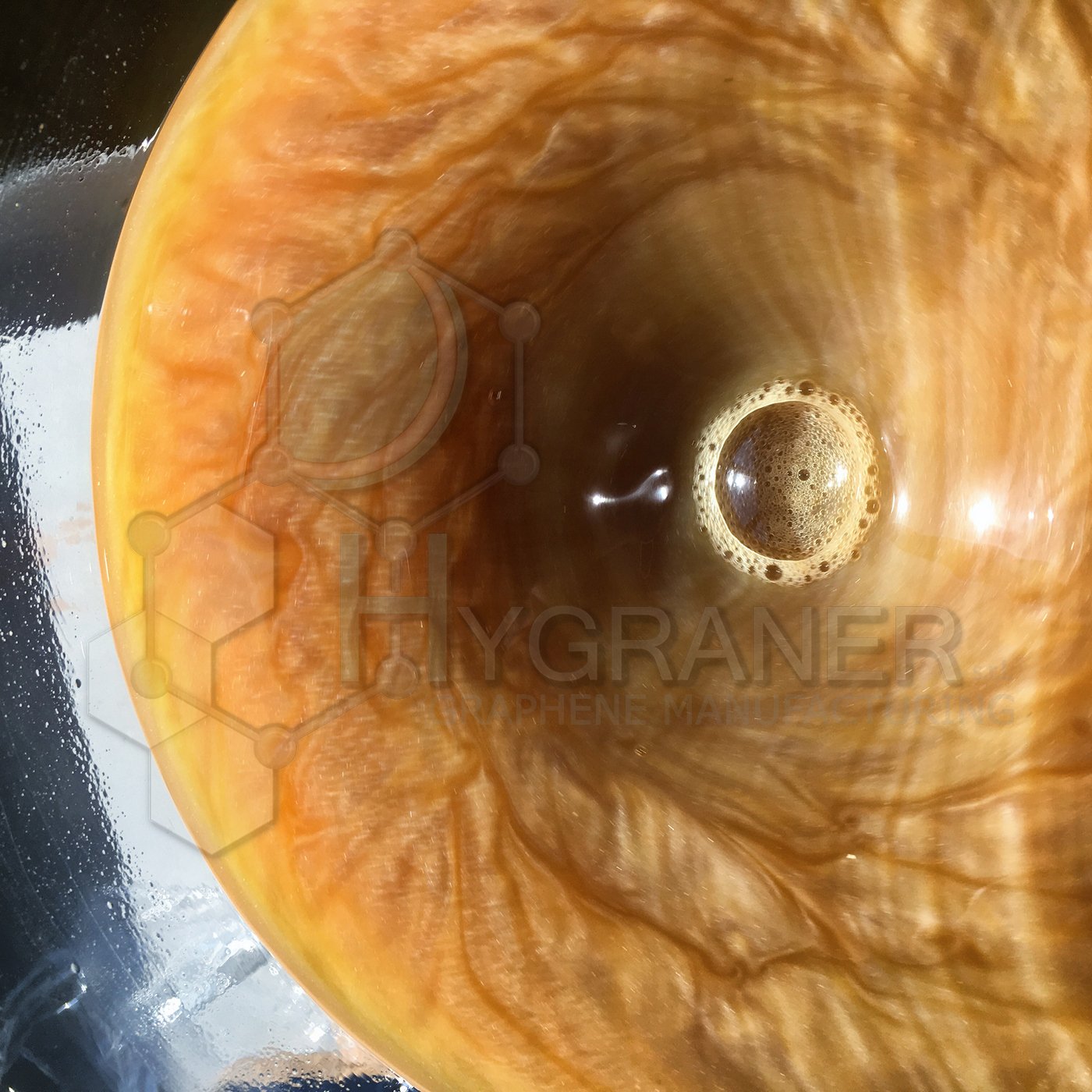

The precursors of Gr, the GO (Graphene Oxide) and the r-Go (Graphene Oxide Reduced) that have hydroxyl (-OH) and carboxylic (-COOH) groups are strongly hydrophilic. Their exfoliation in water or in other polar solvents is facilitated, given the increased distance between floors (and the relative decreased interaction) caused by the presence of oxygenated groups.

The GO is much less conductive due to a higher distance between floors.

In most cases, in order to effectively bind Go, or r-Go to other materials, it is necessary to modify the geometric, electronic structure (with covalent bonds), or insert other stable modifications (due to weak interactions); that is, it is necessary to functionalize the precursor.

Thanks to the availability of these hydroxyl, carboxylic and epoxy groups on the surface, it is therefore possible to modify the reactivity of the material by introducing a wide variety of new molecules according to production needs.

Furthermore, functionalization facilitates the dispersion of nano-materials (Graphene). A good dispersion guarantees the stability of the bond between Graphene and the material to which it is bonded.

The different synthesis methods, the starting materials, the type of functionalization affect the chemical-physical characteristics of the Gr, or of the precursor and consequently of the finished product, made with them.

Our different types of Graphene are selected to improve:

- the adhesion between materials;

- the electrical, thermal, or photoconductivity of materials;

- resistance to certain chemical agents;

- mechanical performance (tensile, bending, load, shear, fatigue, compression, abrasion, etc.);

- impermeability to certain gases, liquids, or salts

- antibacterial and viricidicity.

These improvements are achieved selectively, both individually and in combination.

Finally, we can offer a type of Graphene capable, in particular conditions, of favoring the growth of other structures spontaneously (self-bonds).