Hygraner produces the First Graphene Meltblown Nonwoven Fabric.

Download SDS data sheet: MELTBLOWN HYPP

In the last year, to face some needs born from the radical change of life, to which we are subjected due to pandemic events, we were the first to produce a non-woven fabric with the Meltblown technique, starting from virgin PP enriched with our functionalized, antibacterial and antiviral graphene.

The microfibers of our Meltblown have a variable diameter from 1 to 3 μm.

Hygraner is now able to produce and sell annual quantities of Graphene Meltblown equal to 128 tons / month.

The physical characteristics of our meltblown are the following:

Fabric height: 0.10-1.6 m

Coils diameter: 40-120 cm

Coil Weight: 7-140 Kg

Weight: 15.00-200.00 g / m2

Color: Only Gray

Thickness: 0.3-3mm

Workability: Thermoformable, ultrasonic weldable, thermally weldable

Tnt Meltblown is intended for the creation of solutions for the medical-health sector – in particular for the manufacture of personal protective equipment, such as: (surgical) masks, gowns, shoe covers, overalls, gloves – for air “Filtration ”, for the Automotive industry and for Footwear Industry.

Our microfiber fabric achieves an effective combination of high resistance to scratches and perforations, with an intact softness to the touch; it totally stops the passage, bilaterally, of microdroplets and aerosol particles. Furthermore, it stops bacterial proliferation (up to 99.9%, tested on bacteria belonging to the Gram + and Gram – strains) that of some micro-fungi and that of some molds.

The fabric can be colored and favors the adhesion of prints.

The fabric is “super hydrophobic”, hypoallergenic, antistatic and non-toxic; it can be sterilized, washed, autoclaved.

The antiviral efficacy is always active, for the entire duration of the fabric. This innovation lies in the fact that the fiber is made up of graphene.

Finally, graphene inactivates 80% of the SARS COV-2 viral load after just 30 minutes. It is also antibacterial. Therefore it also eliminates bad smells.

Compared to a standard meltblown fabric without graphene, it has better breathability, greater freshness. These aspects are related to the property of graphene to be an excellent thermal conductor. Consequently, the fabric guarantees a high level of comfort in cases where it is used, for example, for the production of face masks. Particularly different types of surgical masks like I-II-IIR, FFP1, FFP2, FFP3 can be made with the graphene meltblown.

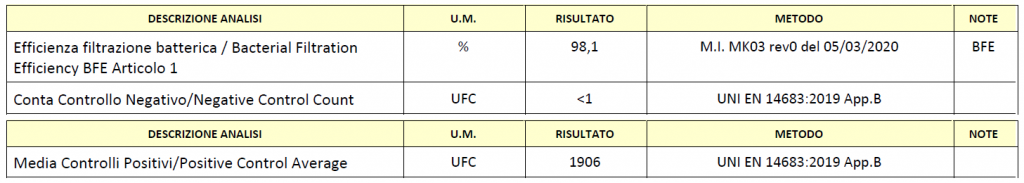

The graphene meltblown has been tested according to the standards:

ISO 18184: 2019 (Determination of the antiviral activity of textile products – Test report n ° 2100056.01 of 21/05/2021).

ISO 10993-12: 2012 + ISO 10993-5: 2009 Annex A – Test report n ° 03544-21 Rev.00 of 14/05/2021.

UNI EN 13795-1: 2019, UNI EN ISO 9073-10: 2005 – Test report n ° 21RA06029 of 26/04/2021.

For specific products it has also been tested according to the following standards:

ISO 22196: 2011, ISO 20743: 2013, ISO 21702: 2019, UNI EN 14683: 2019, UNI EN 13274-7: 2019, UNI EN 149: 2009

At the end of their life these fabrics can be recycled and reused for the same purpose, or transformed into filters for the desalination of marine waters, or for the capture of heavy metals and / or fuel oils (in water) – oil absorbent bag.

.

Download SDS data sheet: MELTBLOWN HYPP